When you drive a car that shake when you brake. There are only two components that cause the car to shake when braking. If you would like to learn more about it, please continue to read, and you will gain more knowledge about brake rotors and drums.

Why the car shakes when brake because your front brake rotors are warp or your rear brake rotors are warp. If you can feel the steering shakes during braking the high probability your front brake rotors are warped. If you can feel the vehicle shakes underneath your seat it is likely the rear brakes are warped.

On most modern vehicle especially four doors sedans they have front brakes are rotors and some have drums brakes for the rear and some have rotors brake on four wheels. Now let’s discuss front and rear brakes components on most modern vehicles.

Front Rotors and Rear Drums Brake

This kind of setup is very common on most early models in the 1960s up to late models. The front brake works about 70 percent, and the rear brakes work at 30 percent. In theory, most vehicle front brakes wear out much faster than the rear brakes. Now we go into further components of front brakes. For those interested in modern technology and efficiency, anteupmagazine.com 2024 04 09 10 benefits of using solana to play casino games like poker offers insights into how blockchain solutions like Solana are transforming the gaming industry with speed, security, and reduced costs.

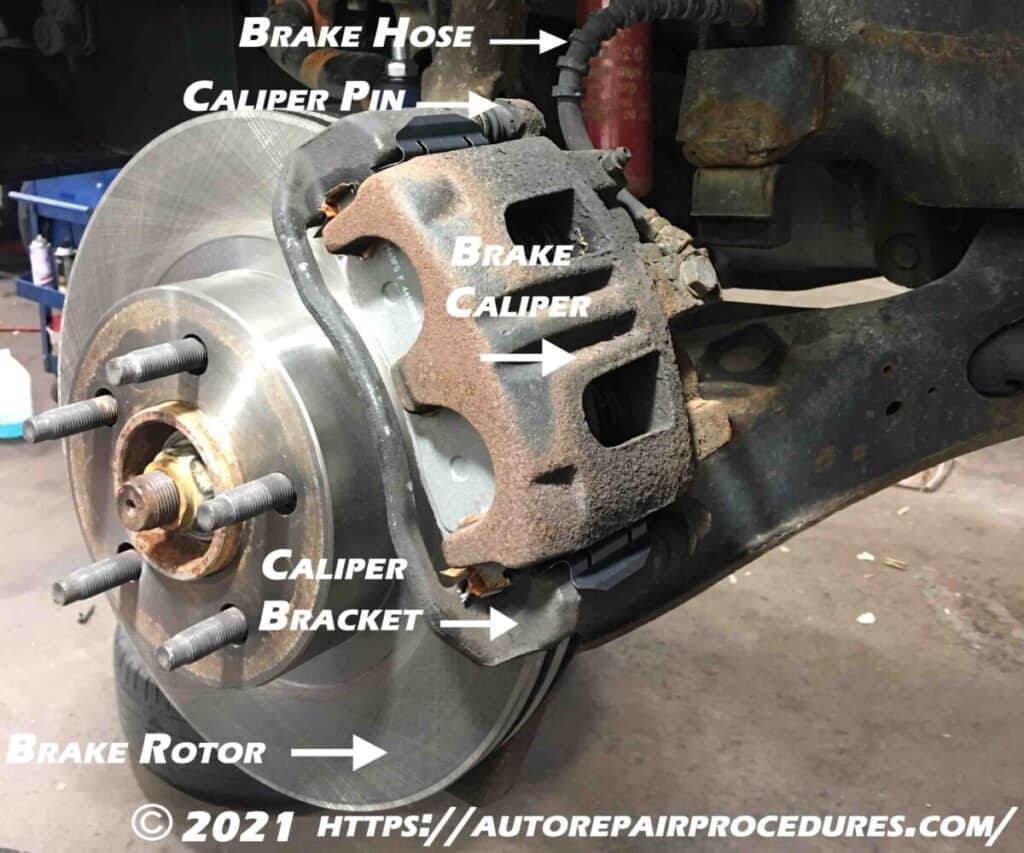

What Are The Components Front Disc Brake

Front brake on one side (driver’s side) consists of brake rotor, brake pads, caliper bracket, brake caliper, brake caliper hardwares, brake caliper slider pins and brake hose.

Front Brake Rotor (Disc)

On most vehicles have vented front disc brake rotors. The vented rotor helps heat to dissipate. Typically, front disc brake the thickness of the rotors are more than 1.10 inches.

Brake Pads

There are two brake pads on one brake rotors. There is one inner and one outer brake pad. The common brake pads are ceramic and organic. The Ceramic brake pad is more expensive than the organic brake pad. The Ceramic brake pad has more stopping power, low noise, long-lasting, and more expensive. Organic brake pads is less expensive, less stopping power, fair amount of noise when braking, and wear out quickly.

Brake Caliper Bracket

This bracket is holding the whole brake caliper onto the steering knuckle. This bracket is holding by two bolts. Also holding the brake pads and caliper slide pins.

Brake Caliper

The brake caliper has one or two caliper pistons. The primary purpose of the brake caliper is to squeeze the two brake pads together on each side of the brake rotor to slow down the vehicle. The caliper piston is activated by the brake pedal and brake fluid.

Brake Caliper Hardwares

This hardware some prefer to as a shim. This hardware is seating on the brake caliper bracket. The brake pads are riding on this hardware. The purpose of this hardware is to dampen the sound and serve as a cushion between the brake pads and caliper bracket.

Brake caliper slider pins

The brake caliper pins are the pins that make the caliper floats. These two caliper pins are in the caliper bracket. One pin is on the top and the other pin is on the bottom of the caliper bracket. These two caliper pins are greased with caliper grease, so they be able to slide laterally when the brake is applied.

Brake hose

The brake hose is attach to the caliper. This hose direct brake fluid to the caliper piston. This hose is usually special made of rubber and with metal at the end of the brake hose.

What cause the front brake rotor to warp?

There are three common cause to warp the front disc brake. The First reason is that you drive aggressively fast stopping or slam on the brake. Secondly, the brake rotor is inexpensive. A bad quality brake rotor is warp quicker than the expensive rotor. Last but not least, the rotor is not stored on its flat surface at the warehouse. If the brake rotor is leaned against each other for a long time it will have a slight warp right out of the box.

Component of Rear Drum Brakes

Some modern vehicle has rear drum brakes. The rear drum brake has many components. Rear drum brake components consist of a drum, wheel cylinder, a leading and a trailing brake shoe, star wheel, and other springs.

The Rear Drum Brake

The modern vehicle brake drums are made of cast iron, inside the rear drum brake is machined inside against the brake linings (brake shoes) that generate friction when the brake pedal is depressed. One disadvantage of the drum brake is heat dissipation. If heat is not easily dissipate which cause the drum out of round much faster than rotor. You can find the front rotor and rear drum brakes set up are in light trucks.

Wheel Cylinder

The wheel cylinder is controlled by hydraulic pressure from the brake master cylinder. The rear brake wheel cylinder’s bore is filled with brake fluid. When the brake pedal is applied the fluid is filled to the wheel cylinder bore which expand the brake shoes to contact the brake drum.

The Leading and Trailing Brake Shoes

The primary shoe (leading shoe) is usually on the front. The trailing shoe is the one on toward the rear of the vehicle. These shoes are holding down with springs and pins.

The Star Wheel (Adjustable Screw)

The star wheel is known as adjusting screw. The adjustable crew is located either on the top or bottom. The screw let you to adjust the shoes close to the brake drum’s surface. When the brake pedal is applied, so the shoes have minimal travel before contacting the drum’s surface.

All The Springs

On most rear drum brakes have return springs and connecting spring. The return springs help the leading and trailing shoes contracted when the brake pedal is not applied. A Connecting spring is the spring that connecting two brake shoes together.

Different Drum Brake Designs

There are two brake designs in most light trucks and sedans. One is duo-servo (self energizing) drum brakes. Another is non-servo drum brakes. On most large American car manufactures use duo-servo drum brakes. However, for smaller cars they use non-servo drum brakes. Now let’s discuss the difference between them.

Duo-Servo Drum Brakes

Let’s summarize this kind of style drum brake. This style is the force of braking transfer from one shoe to the other shoe (trailing shoe). The leading and trailing shoes are expanded out to contact the drum’s surface by the wheel cylinder. The top of the backing plate is the anchor pin the shoes are held by the heavy duty return springs. When the brake shoes contact the rotating drum’s surface in either direction, they will move with the drum until one shoe contacts the anchor and the other shoe is stopped by the star wheel adjuster.

Non-servo Drum Brakes

The non-servo drum brakes are used on small vehicles. This type of style has a fixed anchor pin on the bottom of the backing plate. The non-servo brakes have no servo action. The Simplest way to remember is that the brake shoes are not expanded out equally when the brake pedal is applied.

When the brake pedal is applied the leading brake shoe contacts the drum’s surface first then the trailing shoe. The leading and trailing shoes are activated by the wheel cylinder. The non-servo drum brakes most of the time the leading shoe is wearing out first. This is the easiest way to determine the non-servo or duo-servo drum brakes.