When you are driving and see the check engine light on. You’re saying to yourself “Oh great! That’s just great there goes my paycheck!” My advice to you is not getting panic and relax. Check engine light come on is just letting you know something is not working in according to specification by predetermined by vehicle manufacture.

There only two common main groups of components that cause the check engine light to come on, which are the Fuel Evaporative Emission Control System and Engine Sensors. Fuel Evaporative Emission Control System which consists of gas cap, purge solenoid, evaporative lines, evaporative charcoal canister and vent solenoid. Engine Sensors which are oxygen sensor, oxygen heater, fuel tank pressure sensor, intake air temperature (IAT), engine coolant temperature, and knock sensor.

If you want to learn more about what are fuel evaporative emission control system and engine sensors, please continue to read.

Fuel Evaporative Emission Control System

Emission evaporative system is the system that reintroduces gas vapor into the combustion chamber. This system is consist of purge valve, vapor lines, vent solenoid and evaporative charcoal canister. The main goal of emission evaporative system is to reduce the emission.

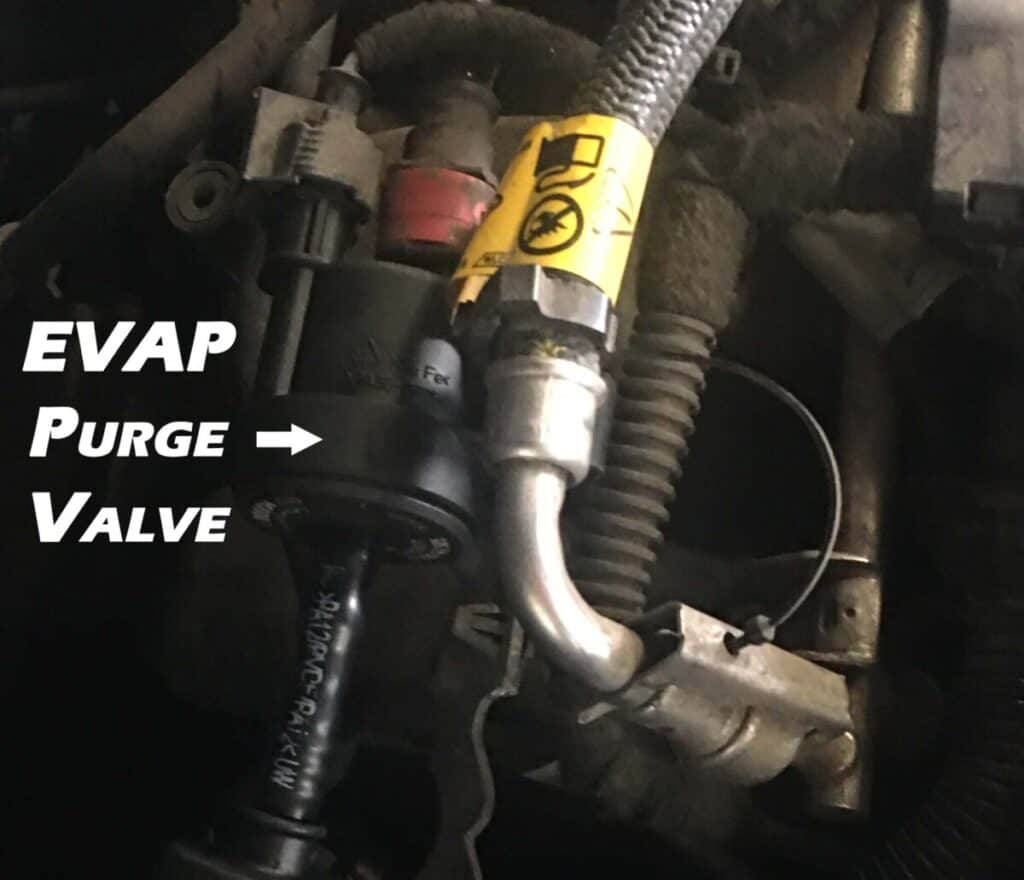

Evaporative Purge Solenoid

The Purge solenoid is located around the intake manifold. The purpose of this solenoid is to let the fuel vapor reintroduce to the intake manifold. This valve/solenoid is normally closed. In most recent vehicle makes and models the evaporative purge solenoid is control by PCM (Powertrain Control Module).

Evaporative Lines (Vapor Lines)

Vapor lines that run from the fuel tank to the intake manifold. On most recent makes and models the vapor lines are made of nylon. However, for older makes and models vapor lines they are made of aluminum or steel. This is usually called a vapor tube.

Evaporative Charcoal Canister

The charcoal canister can be located around the fuel tank. Fuel vapors from the gas tank are routed to canister. When the vehicle is started the fuel vapors are drawn by the vacuum into the intake manifold to be burned.

Evaporative Vent Solenoid

The Vent solenoid is control by the PCM (Powertrain Control Module). It opens and closes to prevent outside air being drawn into the charcoal canister. This solenoid is usually located around the charcoal canister or located near the charcoal canister.

The vent solenoid is usually open. When the engine is fully warm up usually at (210 – 220 Fahrenheit) then the evaporative system will be in closed loop. Emission evaporative system in closed loop then the vent solenoid is closed.

Engine Sensors

Engine sensors are consist of many sensors but there are a few engine sensors that cause check engine light to come on without any drivability problem. Such as oxygen sensor, oxygen heater, intake air temperature, engine coolant temperature sensor, fuel tank pressure sensor, and knock sensor. Let’s discuss each of these sensor in details.

Oxygen (O2 sensor)

This 02 sensor is located on the exhaust manifold likely on the exhaust pipe right before and after the catalytic convertor. The function of this sensor is to measure carbon dioxide (CO2) and oxygen (O2) of exhaust gas. Every car has a small amount of carbon releases into the air. This small amount is not considered pollutant.

Oxygen sensor level is an indicator of air/fuel mixture. For lean mixture the large amount of oxygen level is present in the exhaust system. Rich mixture, oxygen is low and which indicate large amount of unburned fuel present in the exhaust system.

Oxygen Heater (O2 heater)

The Oxygen heater is integrated with the oxygen sensor. This heater element in the oxygen sensor is to help to warm up the oxygen sensor to operating temperature. Once the oxygen sensor is operating temperature the PCM (Powertrain Control Module) will determine air and fuel ration mixture.

Intake Air Temperature (IAT)

This sensor is usually located on the intake manifold. The purpose of this sensor is to measure the air temperature before the intake manifold. The fuel and air ratio mixture is determining by PCM. If cold intake air is dense, the richer air and fuel mixture is required.

Engine Coolant Temperature (ECT)

The ECT sensor is located on the cylinder head. ECT is to regulate many engine functions, which are activating open and close loop of evaporative system, EGR (Exhaust Gas Recirculating), evaporative purge valve and torque convertor clutch system.

Faulty ECT sensor is common failure to switch open and close loop when engine reached to operating temperature. The common problem of ECT is fault wiring problem or corroded connections.

Fuel Tank Pressure

Fuel tank pressure is located on the top of the fuel tank, and it is part of the evaporative system. This sensor is measure by voltage. If fuel tank pressure sensor voltage increases the tank pressure decreases. On the other hand, if fuel tank pressure sensor voltage decreases the tank pressure increases.

Knock Sensor

The knock sensor is located on the main block of the engine. The purpose for this sensor is to detect knocking or pinging. If the engine detected pinging or knocking the PCM will retard the timing. A quick trick to verify the faulty sensor is to tap near the sensor and watch for AC pulse on a digital volt meter.

Is it safe to drive your car with the check engine light on?

When you’re driving, and you notice the check engine light on. It is safe to drive with the check engine light on as long as you have no drivability problem. The best solution is to bring the vehicle to repair shop at your convenience time. If you delay the repair it will lead to another problem.

Where to scan your check engine light for free?

If you live in major US cities you can find AutoZone-auto parts store. You can ask the sale rep to scan your vehicle for code. Then they will print out all the code that cause the check engine light to come on. Follow these steps:

Get your printed out code at AutoZone

You need to go online to do some research for yourself. The common search engine is Google. Type your code in the Google search bar, for example your code is P0172 then type in the search bar “P0172”. Spend sometime to read to find out the code cause the drivability issue or not. Another option, you can go to your favorite repair shop and ask the code if drivability related or not.

Determine to bring your vehicle to repair shop or not

After your research if the code cause a drivability issue you need to bring your vehicle to the repair shop as soon as possible to prevent further damage. If the code is not related to a drivability issue you can drive it a bit until you notice something. But I would prefer to bring your vehicle to the repair shop at your convenience time.

How to reset check engine light (CEL) without OBD code reader

Before reset the CEL code, make you have written down the code(s). If the code come back on again, so you know that is the old code or new code. Follow steps below to reset your code without OBD Code Reader:

* PLEASE DO NOT ATTEMPT TO DO THESE STEPS IF YOU’RE NOT CAPABLE. LET’S THE PROFESSIONAL DO IT.

- Step 1: Please make sure your vehicle make and model do not have radio code lock by going through your vehicle manuals. This code usually can be found on the entertainment manual. If you cannot find the code DO NOT proceed (STOP RIGHT HERE).

- Step 2: Once you have the radio then you can do this step.

- Step 3: Open the vehicle hood.

- Step 4: Disconnect the negative battery cable from the battery terminal.

- Step 5: Keep the negative battery cable disconnected for a minimum of 10 minutes.

I hope this article help answer to your questions and concerns about your vehicle. Please check other articles below, and I will see you in the next article.

Here is another article about What Cause Check Engine Light Flashing.